Research

Micro-architected solids

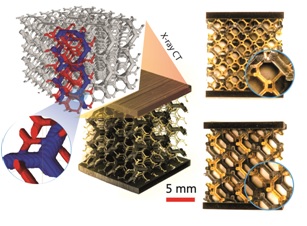

Micro-architectured solids are an emerging new class of engineering materials, ranging from gyroid foams on the nanoscale to 3D composites at the micron scale and above. They offer the opportunity for design at the microstructural level and can lead to new combinations of properties, such as high thermal resistance, high toughness and high strength at low weight. The group has invented several such materials long with new manufacturing and test techniques including in-situ 3D X-ray tomography methods for ceramic/metal composites (cermets).

Structural materials under high rate loading

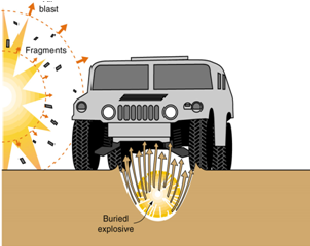

The scope of this work is very broad: it encompasses fluid-structure interaction effects between blast waves and structures to the invention of new structural materials for blast-resistant sandwich panels. An important element of the work has been the development of laboratory-based simulators of blast loading dynamic events. This experimental work has been accompanied by the development of new simulation tools to perform large-scale computations of these dynamic events, e.g. coupled discrete particle/finite element methods to simulate granular loading of structures.

Plasticity on the micron scale

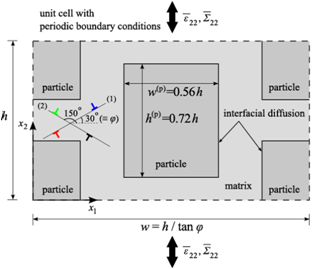

How do dislocations collectively dictate the high temperature creep behaviour of engineering alloys? We have developed computational mechanics methodology for the motion of discrete dislocations (both climb and glide) coupled to vacancy diffusion. This explains, for the first time, the origins of the continually increasing creep strain rates in superalloys and the role of particle size effects in metallic composites at high temperatures.

Mechano-biology of cells and tissues

We have pioneered the development modelling frameworks for the mechano-sensitive response of eukaryotic cells with a focus on the role of the cytoskeleton and focal adhesions. A key insight was to develop an ensemble for the homeostatic equilibrium of cells even though from a conventional thermodynamics viewpoint, living cells are ultimate examples of non-equilibrium systems. This has led to the development of a statistical mechanics framework for living cells, on par with conventional statistical thermodynamics but yet accounting for the non-thermal fluctuations of cells and their subcellular components.

Failure of solid electrolyte Li-ion batteries

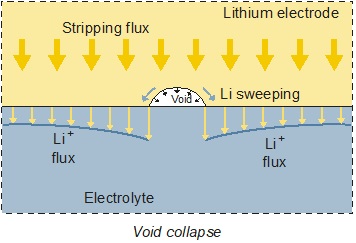

Solid-state cells composed of a ceramic electrolyte and Li metal anode have the potential to deliver enhanced safety along with higher specific energies compared to liquid electrolyte Li-ion batteries. However, stiff, and strong ceramic electrolytes can suffer short circuits resulting from the penetration of Li filaments through the ceramic at charging currents above a critical current density. We have developed coupled electrochemical-mechanical variational principles to understand how the electrochemistry of these cells drives mechanical failure. Our focus is on developing an understanding of how well-established ideas such as Butler-Volmer kinetics need to be modified in the context of these solid-state batteries.

Data driven mechanics

Using state-of-the-art advances in visualization and data assimilation, we obtain billions of high fidelity point cloud datasets in terms of measured defect distributions in the printed specimens including cracks and voids, as well as deformations (strains) at every material point via Digital Volume Correlation (DVC) on spatio-temporal XCT scans. Employing such extensive in-house data, we leverage recent foundational advances in machine learning and graph neural networks (GNNs), to design new additively manufactured materials with fully tailorable mechanical properties.